As a premier geotechnical engineering consulting company with a team of experienced professional engineers and certified technicians, Findling, Inc. has provided professional engineering, and construction monitoring and material testing services for over 500 small and large projects throughout Maryland and Washington DC, as well as Virginia, West Virginia and Pennsylvania. Some of our projects are described below.

Baltimore, Maryland

This project consisted of improvements at the entrance to the UMBC campus. The proposed construction included roadway widening and installation of a roundabout, a new roadway and walkways around the existing parking garage, and Storm Water Management Facilities.

Findling's Geotechnical Investigation scope consisted of:

- Drilling 10 SPT borings to 10-foot depths for roadway widening

- Drilling 20 SPT borings with continuous sampling to depths of 10 feet each for the SWM Facilities

- Determining infiltration rates by performing 12 in-situ infiltration tests adjacent to the SWM boring locations in accordance with MDE Pond Code 378

- Performing specialty laboratory tests on selected soil samples

- Preparing a Geotechnical Data Report with summary of subsurface profiles and field and laboratory testing data to aid in the design and construction of the proposed improvements

This US 113 project begins just North of MD 365 and ends at Five Mile Branch Road. Proposed construction consisted of providing two additional lanes to create a dual four-lane divided highway and new service roads consolidating US 113 access points with adjacent properties. Additional improvements included road tie-ins with existing dual highway sections, new and reconstructed/ rehabilitated pavements, an at-grade railroad crossing of US 113, a 70-ft span prestressed concrete slab bridge over the Purnell Branch, road culvert extensions and replacements/ rehabilitations, drainage systems and SWM facilities, intersection lighting and signal modifications. Findling, Inc. was part of the design team that included RJM Engineering, a subconsultant to Wallace Montgomery (the engineer of record).

Geotechnical Engineering services provided by Findling included subsurface explorations consisting of drilling and SPT borings, in-situ testing utilizing CPT and DMT, in-situ infiltration tests, specialty soil laboratory testing, and preparing a Geotechnical Engineering report to aid in the design and construction of one bridge structure, two retaining walls and replacement/ extension of five culverts, Storm Water Management facilities, grading considerations and pavement structures.

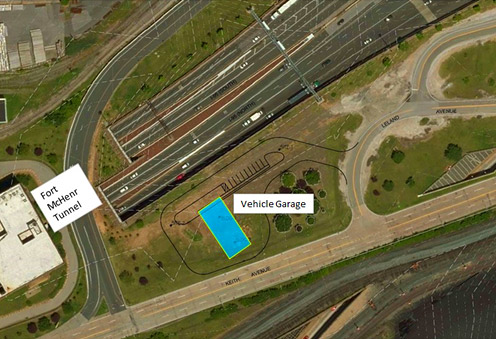

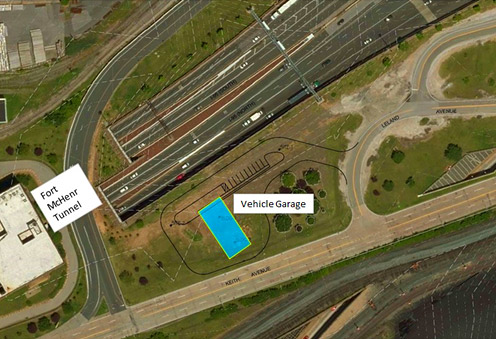

Baltimore, Maryland

The project site is located on the north side of the I-95N Harbor Tunnel exit, and bounded by Keith Avenue on the south, Leland Ave on the east, and I-95N Exit 56 ramp on the west. Proposed construction included a single-story 50' by 100' vehicle garage building, and a parking lot located north of the building. The building has four 25-foot wide bays with maximum column loads of 30 kips. The ground floor slab-on-grade construction was planned with 200 psf loading.

Findling's Geotechnical Investigation tasks included the following:

- Drilling 2 SPT borings with sampling to a depth of 90 feet in the building footprint

- Drilling 2 SPT borings to a depth of 10 feet each in the parking area

- Temporary containing drill spoils and cuttings in drums for final disposal off-site by a licensed waste hauler

- Performing laboratory tests on selected soil samples

- Preparing a Geotechnical Engineering Report to address pavement section design, and the deep foundation options including Timber Piles, Helical Piles and Auger Cast-in-Place Piles for support of the building

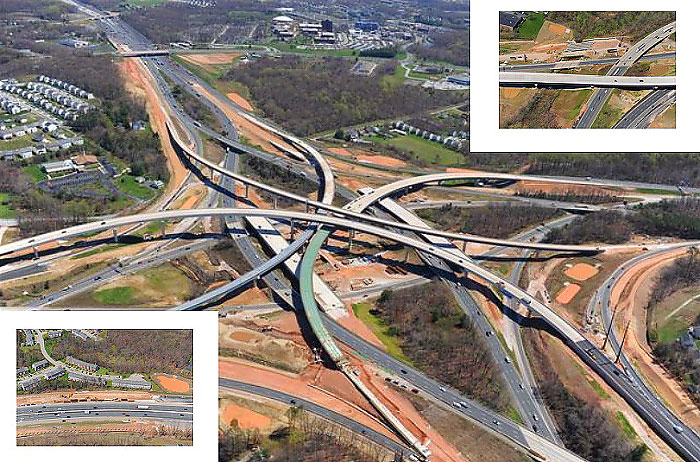

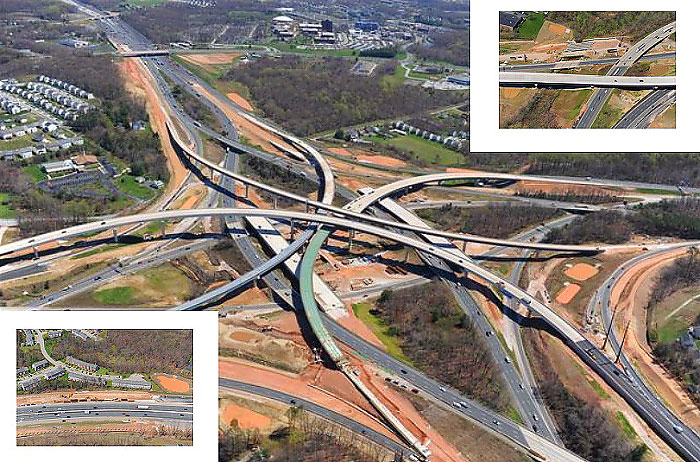

Findling provided Construction Inspections and Material Testing Services on the I-95 Section 100 Project in Baltimore Maryland for the MDTA (Maryland Transportation Authority). Our responsibilities included conducting on-site construction inspections and testing of soils, concrete, steel and hot mix asphalt (HMA); keeping daily records of work performed; keeping daily records of labor, equipment and material on the site and hours worked; preparing field sketches of constructed work; preparing quantity estimates; and attending/ conducting construction progress meetings. Findling served as the owner's representative "eyes and ears" on site to protect his interest and minimize contractor claims by keeping detailed and accurate records. We established continuous coordination and communication between MDTA and contractor.

Findling provided more than 5 certified technicians and inspectors at the various intersections, bridge, ramp and roadway widening sections of the project, and an inspector for the I-95 ETL laboratory (by Maryland Department of Transportation) located near the Section 100 Project Management Office.

Findling was retained to provide Geotechnical Engineering, Construction Oversight, Materials Testing Services, and Geotechnical Instrumentation for the construction of the Cox Creek Dredged Material Containment Facility. The project site is located on the west bank of the Patapsco River just south of the Francis Scott Key Bridge in NE Anne Arundel County, Maryland. The facility covers an area of about 115 acres. This site was initially developed in the mid 1960's for disposal of dredge material, and consisted of a perimeter dike on the north, east and south sides. The facility was abandoned in the late 1960's and 1970's. The Maryland Port Administration purchased the facility and led a contract for the rehabilitation and raising of the perimeter containment dikes so that the facility could be used again for disposal and dredge material from the inner harbor. Findling was retained to provide Geotechnical Engineering and Construction during construction of the facility

The services Findling, Inc. provided for this project included:

- Test borings and in-situ testing to evaluate subsurface conditions and strength characteristic of foundation soils

- Geotechnical engineering design for the containment dikes and instrumentation during construction

- Installation and monitoring of geotechnical instrumentation including piezometer, inclinometer and observation wells

- Full time field engineering services for slurry wall construction

- Full time materials technician to monitor and test fill placements and geotechnical consultation during construction

- Laboratory testing of soil and slurry wall samples

- Attended progress meetings and other meetings with design team and contractors as requested

Findling, Inc. was retained to provide Geotechnical Engineering services for the design of the Masonville DMCF at the Masonville Marine Terminal. The project consisted of designing a containment facility for placement of dredge material from the Baltimore Inner Harbor area. The proposed facility consisted of an earth embankment (dike) about 5,000 feet long to be built in the Middle Branch Patapsco River between the existing Masonville Terminal and the Ferry Bar Channel, extending about 1000 feet into the river. The dike was designed to a maximum height of El. +42 over an area of about 116 acres to provide a design storage capacity of about 16 million cubic yards of dredge material.

In addition to design of the earth embankment, Findling evaluated the subsurface condition within the footprint of the perimeter dike to identify a source of soil for earth dike construction and increase storage capacity, and evaluated the permeability of the proposed dike section for seepage analysis.

Masonville DMCF Dike Raising Phase III

Masonville DMCF Dike Raising Phase III

Initially the dike was to be constructed to El. +10 with on-site soil then raised to El. +42, using reclaimed dredge material within the facility. Initially 5 dike alignment options were considered, and after an initial evaluation of subsurface conditions, one alignment was selected for final design.

Another aspect of the project included relocation of a 48 inch water line between Fort McHenry and the Masonville Terminal which passes under the proposed containment facility. Findling provided Geotechnical Engineering services associated with the water line relocation.

The services Findling, Inc. provided for this project included:

- Subsurface investigation on water and land

- In-situ testing to evaluate strength parameter for dike foundation soils

- Evaluation of subsurface soil conditions within the footprint of the containment facility for use in dike construction

- Designed the earth embankment to a maximum height of El. +42 in stages over the life of the facility

- Assisted with preparation of specification for dike construction and dredging

- Met with MPA and Corp of Engineers to review design

- Provided geotechnical design parameters for thrust block design, cofferdam and pipe line support for 48 in. water line relocation

Findling performed a Subsurface Investigation for the I-695 over MD Route 26 and Milford Mill Road Improvements Project. The scope of this work included drilling test borings in soil and coring rock at the location of the bridge structure, abutments and retaining walls. In addition, borings were drilled for the lane widening, and new ramps and modification of existing ramps. Test borings were also drilled for the proposed Storm Water Management (SWM) facilities, and in-situ infiltration tests were performed. The test borings in the existing roadway were performed during restricted work hours, including night work on I-695 with Maintenance of Traffic (MOT) during the drilling operations. The test borings in the roadway were backfilled with grout in order to minimize future subsidence, and the surface was patched with cold asphalt patch.

The samples from the test borings were transported to our laboratory for additional testing. In the laboratory, moisture content, Atterberg limits, grain size analysis and Proctor Compaction Tests were performed on selected samples. In addition, CBR testing was performed on selected samples to aid in the design of the pavements.